UNIVERSAL TESTING MACHINES

Universal Testing Machines

- Hydraulic Mechanical Dial Type UTM – Closed Head Design, Single Acting Ram

- Hydraulic Electronic Microprocessor based UTM (Closed Head Design)

- Hydraulic Computerized UTM

- Computerized, Servo Controlled UTM (Single Acting Ram)

- Hydraulic UTM (Open Head, Single Acting Ram)

- Computer Controlled Electro-Mechanical UTM (Ball Screw Driven)

- Microprocessor-Controlled UTM

- Electro Dynamic Testing Machine

- Electrodynamic Testing System EDTM-10

- Electrodynamic Testing System EDTM-100

Computer Controlled Electro-Mechanical UTM (Ball Screw Driven)

EDW Series is a new kind of electronic universal testing machine produced by ENKAY, which adopts the most advanced and reliable load frame structure of ball screw electric mechanical universal testing machine in the world. The driving system adopts the Japanese AC servo system and motor. The PC controlling system is able to realize the close-loop control of the parameters such as loading force, specimen deformation and crosshead stroke etc. The system realizes the screen display, online diagram drawing, testing curve changing, fold curve collation and auto analysis of test results, creation of test reports. Especially, the application of the control mode can be manual control or computer programming control which makes the cyclic tests so easy.

By simply switching of different accessories, EDW series Universal testing machine can make tests on most of the materials and components to suit your needs.

FEATURES

- Complete computer controlled: The whole measuring and controlling system adopt a specific PC control card used for testing machines, which has very high reliability.

- Supporting multi-transducers the database management of the test data which are stored according to the standard format; facilitating other software to analyze and transfer.

- Perfect programming by auto program control, every control mode can smoothly shift from one to another. Fulfilling the test requirement of all kinds of materials with every test standard at home and abroad.

- Control software has the auto-adjusting function of test hardness, which assures that the system works with every kind of specimen hardness.

- Perfect graphic function for the arbitrarily magnifying, decreasing, equaling, adding, indicative display and print of all kinds of test curves, the test point searching as well as the simultaneous display and print of several kinds of test curves. Data processing supposes self-disposing and input disposing of graphic human-computer interaction, which facilitates the check and contrast of the test result.

- The user can self-define the output of the test report, which makes the report format very high flexibility.

Modularization design facilitates software upgrading, function spreading as well as the second development.

Standard Accessory for WDW Series:

- Tension grip jaws (Wedge action Grips): 1 Set

- Grips for round specimen: 4pcs of each

- Grips for flat specimen: 4pcs of each

- Compression test attachment: 1 Set

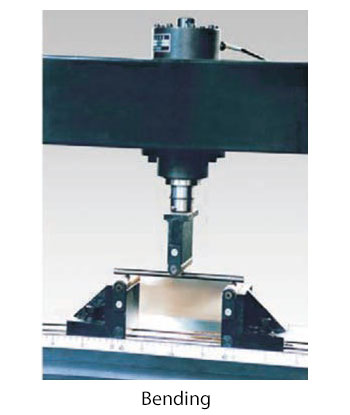

- Bending test attachment: 1 Set

- Tool kit: 1 Set

- Extensometer: 1 Set

- Photoelectric coder: 1 piece

- Load cell: 1 piece

Data-processing system:

- ENKAY plug-in ready to use controller: 1 set

- Software Wintest: 1 set

- PC + Printer: 1 set

- Servo speed adjusting system: 1 set

Software Introduction

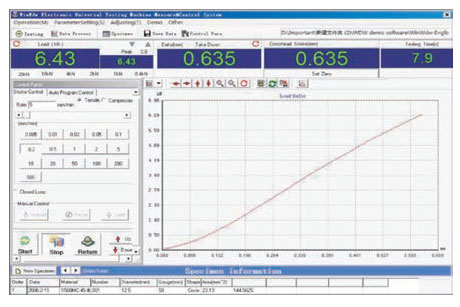

Win Test Control Software

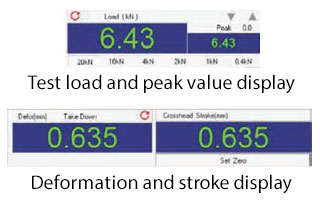

Easy to control and friendly interface MS windows based interface, easy and fast to reach different functions, suitable for most of the operators using habits. Full digital display and computer control Adopt ENKAY Controller, Fast response and reliable to parameter gathering. Realize the digital adjustment and zeroing of LOAD, DEFORM, and DISPLACEaMs EweNllT a s PID parameter adjusting.

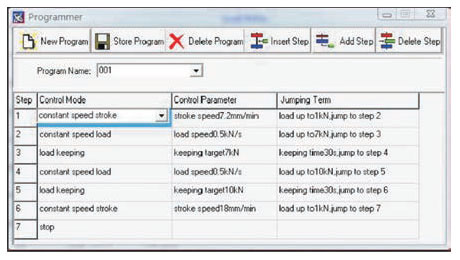

Manual or Program control of test process Win-Test Software of provides multi-functional control mode: STROKE/ PROGRAM.

Stroke and Program Control Mode

In stoke control mode, operator can define customized test speed to conform with different test standard. Preset limit position and return position will secure the safety and return the crosshead automatically after test finished.

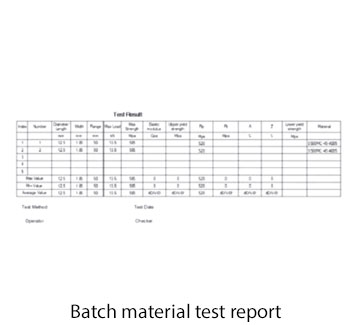

In program control mode, the testing machine is controlled by conditional programs, operator can input each condition to regulate test process, software can realize constant parameter control through Batch material test report this function.

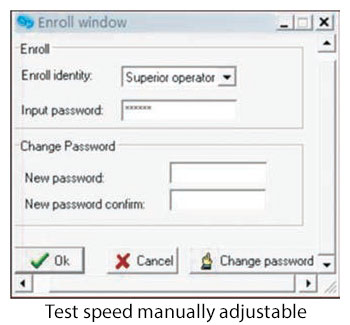

Multilevel Authorization Access The software regulated different access level to protect machine calibration parameters.

Reliable to secure the information safety and easy for software Maintenance.

Software Features:

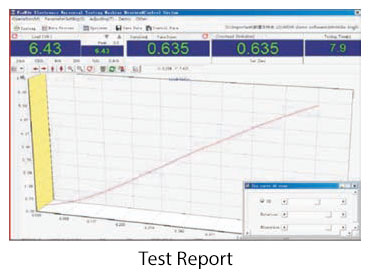

- Perfection of diagramming functions.

- Realize the testing diagram online display and reproduction.

- Zoom in or out the test diagram at any place with any rate.

- Auto suit the diagram according to display resolution.

- “Diagram fold” to enable with material difference analysis.

- Print “section diagram” function

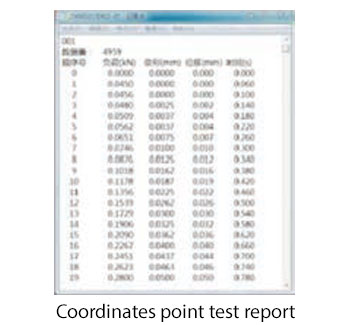

- Coordinates point tracing to check the test results in each point.

Test Report Creation

- The Win-Test provides a different way to create a test report

- Single material test report

- Batch material test report

- Customized test report

- Coordinates point test report

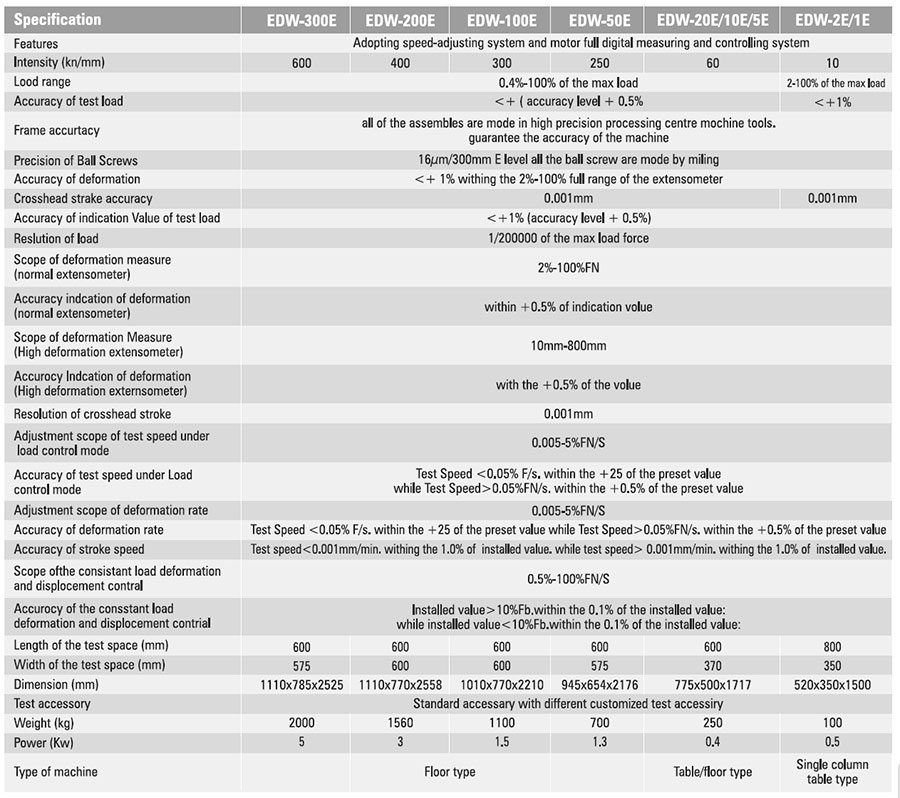

MAIN TECHNICAL SPECIFICATION

- Perfection of diagramming functions Realizes the testing diagram online display and reproduction.

- Zoom in or out of the test diagram at any place at any rate.

- Auto-suit the diagram according to display resolution.

- “Diagram fold” to enable material difference analysis.

- Print the “section diagram” function

- Coordinates point tracing to check the test results at each point.

Machines of other capacities and custom features can also be manufactured as per requirements.