UNIVERSAL TESTING MACHINES

Universal Testing Machines

- Hydraulic Mechanical Dial Type UTM – Closed Head Design, Single Acting Ram

- Hydraulic Electronic Microprocessor based UTM (Closed Head Design)

- Hydraulic Computerized UTM

- Computerized, Servo Controlled UTM (Single Acting Ram)

- Hydraulic UTM (Open Head, Single Acting Ram)

- Computer Controlled Electro-Mechanical UTM (Ball Screw Driven)

- Microprocessor-Controlled UTM

- Electro Dynamic Testing Machine

- Electrodynamic Testing System EDTM-10

- Electrodynamic Testing System EDTM-100

Microprocessor-Controlled UTM

Microprocessor-controlled Universal Testing Machine designed for determination of tensile, flexural and compressive properties of polymeric materials including plastics, elastomers, fibre/ filaments/ yarns, FRP’s, films/sheets, woven sacks, geo-membrane, etc.

Standards:

EN 10002-2, ISO 7500-1,BS 1610,ASTM D 638,ISO 527, ASTM E4

Capacity:

100kN (Low Cycle Testing upto +/- 50kN.)

Control System:

Microprocessor Controlled with 64 Bit A/D Signal Conversion

Cross Head Speed / Test Speed:

- Maximum Test Speed: 500 mm/min

- Minimum Test Speed: = 0.0005 mm/min

- Accuracy: 0.1% of set speed

- Return Speed: Up to 500 mm/min. Speed selection is provided via computer software and can be programmed in the test cycle library.

- Resolution of crosshead speed: 0.05 µm/min

- Jog Speed: Provision to specify jog speed to protect samples of light materials while mounting using a hand-held controller with a rotary potentiometer.

- Maximum force at full speed: 100 kN

- Position control resolution: 0.00005 mm

- Position measurement resolution: 0.02 µm

- Total crosshead travel: 1250 mm min

- Total Vertical Test Space: 1000 mm min

- Space between columns (horizontal daylight): 550 mm max

Load/Displacement Reading Interchangeability:

- Load N, kN, g, kg, lb

- Displacement mm, cm, inch

- Load Measurement Make Interface USA ( Model :1200, Capacity 100 Kn)

- Load Cell Capacity 100 kN (1 no.) with provision for easy attachment as required for normal test and test using environmental chamber

- Accuracy Within ± 0.5% of indicated force

- Repeatability ± 0.25% of reading or 0.005% of capacity

- Resolution 0.0004% of capacity

- Load Cell Calibrator 100 kN (1 no.)

Strain Measurement:

- Make: Enkay

- Model EKE-EXTLR (Long Travel Extensometer

- Extensometer: Contact type extensometer for rubber sample testing at room temperature

- Vertical travel: 900 mm

- Resolution: 25 micrometer

Grips & Fixtures:

For all load cells (100 kN, 10 kN , 1KN & 100N)

- Grips: Pneumatic & manual type wedge grips

- Specimen thickness: 200 µ to 10mm

- Specimen length: 2 cm to 20 cm

- Specimen width: Upto 5 cm

- Pneumatic grip: Upto 10 kN for films & fibers

- Compression test fixture: Complying to ASTM D 695

- Flexural: 3 point bend and four point jig fixture complying to ASTM D 5943 for specimen support up to 10 kN and adjustable span 20-200 mm or equivalent Fixtures Tensile grips, mechanical wedge grips, pneumatic vice grips suitable for low and high temperature (-70 to 200 °C) testing & can be accommodated into environmental chamber.

Environmental Chamber Make: Enkay

- Model: EKE-EC-THW

- Operation Temperature range: -70° to +200°C Accuracy1.5°C

- Chamber Dimension: 300 x 300 x 600 mm (W X D X H) approx. with suitable Fixing and pull in pull out arrangement.

- Cooling Medium: Liquid Nitrogen (Dewar Flask of required capacity is provided) with accessories for low temp testing capabilities.

- Machine Control: An integrated control system and measuring electronics with dedicated Graphical UI application software to performing the tests is supplied.

- Measuring Electronics: A computerized Data Acquisition Electronics with signal conditioning amplifiers with sufficient bandwidth for measurement of Load and Strain, Cross head position with integrated application software is provided.

- Data Acquisition Sampling Rate: 5000 HZ using Enkay Hydrid 6 Channel DAQ 100% Designed and developed in India.

- Analog Output: Analog output to connect to external recorder corresponding to measured Load, Extensometer at ± 10V Full Scale or for auxiliary usage of this voltage output.

- Remote Control: Remote Control Pendant is provided to move the Cross head, Grippers, Emergency Stop etc.

Control Mode ENKAY –MAT BENCH

100% designed and developed in India

- a. Load control.

b. Strain control.

c. Stress-control.

d. Speed control.

e. Position Control - Test Mode

Tensile test / Compression test / Flexural tests - Methods

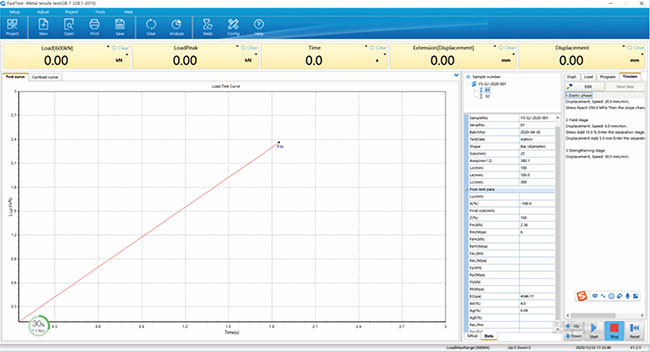

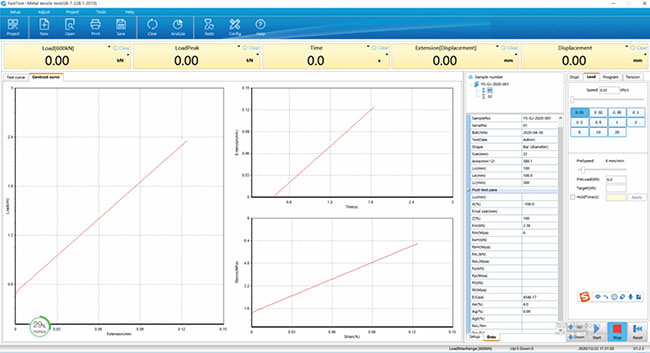

Creates variety of test methods as per the popular ASTM and ISO standard and also capable of creating customized test setups to match user unique requirements. - Graph Display on Screen

Able to plot/display real time online illustrative graph on display screen for as under:

a. Load Vs Displacement (i.e. Crosshead)

b. Load Vs Extension (from extensometer)

c. Load Vs Time.

d. Stress Vs Strain.

e. Displacement Vs Time.

f. Strain Vs time - Data measurement and storage

Machine measures & records following parameters, in SI units or User Selected Units.

Ultimate Tensile Load (kN, N, kg)

Breaking Load

Yield Load

Cross sectional area (mm2, cm2, m2)

Ultimate Tensile Strength (MPa, N/cm2, N/m2)

Yield Stress

Proof Stress

Gauge Length (mm, cm, m)

Elongation at specified load (%)

Load at specified elongation or travel length (N / kN / kg)

Elongation (%)

Modulus of Elasticity

After test, data sheet and graph automatically stores in defined

folder (data sheet in excel and pdf format, Graph in JPEG, bitmap,

pdf etc) apart from software or any external storage device. - Area Calculation

Readily accepts variety of sample geometry like, Rectangular, Cylindrical, Tube, ring etc. with option to enter the cross section area directly for irregular shaped sample. Automatic area calculation. (customized as per user requirement.)

Software and its additional Specification:

- The software has three level of user access based on login name and password protection.

- Only ADMIN control defines the access to user.

- Multiple live display windows are available fo simultaneous display.

- The software allows the user to define significant digits or decimal places for all live displays.

- Software has auto scaling plots.

- The software allow recording of a test with a USB camera device (such as a webcam).

- The software allows for result to display in the live display after test.

- The software allows peak, modulus of elasticity and yield calculation to be evaluated real-time during the test and displayed in the live displays.

- Machine – Controller Interface through USB High Speed Data Transfer rate of 5 Khz is provided.

- Software provides calculation of key test results such as Peak values, Break values, UTL, UTS, Young’s Modulus, Yield stress and strain, 0.2% Proof stress and strain, Area under the curve, loads @ specified elongations, elongations @ specified loads etc.

- Software provides automatic printable view of Graph and Report with Statistical Analysis such as Mean, Min, Max, Std Deviation etc. for multi specimen testing.

- Raw test data accessible in Microsoft Excel.

- It stores test data and results to hard disk in ASCII delimited format for easy import into popular Spread-sheet and database programs.

- Software is perpetual with all latest advance modules.

Computer and Printer:

- Standard latest computer system with updated configuration (Windows 10) compatible with the current as well as the upgraded software version along with color printer and all other requisite accessories is provided.

Control panel for manual operation:

- The UTM is operable in Manual mode in case the entire computer/software crashes. The system is connected to a printer / recorder in such case and stress/strain graph or load/elongation can be recorded.

Standard Accessories:

- Tensile Model, EK TT GP

- Compression, EK CT AC

- 3 Point Bending, EK BT AC

- 90° Peel tester for adhesive tapes EK PT AC

- Fixture for testing of friction of plastics films EK FT AC

- All grips comply to IS / ASTM / ISO standards for Plastics, Elastomers, FRPs and filaments / Yarns.